Mainly considering the 2 perspectives of mold design and mold processing.(In addition, the defects of the product itself will also affect the accuracy of the mold)

01 Mold design

In the early stage of the product, the product flow analysis was made, and the more reasonable product inlet was found to reach the balancing of the glue. The mold locking force was in the scope of the injection molding machine. The product deformation was relatively small.

Product molding: Try to design the product as a plane rather than the curved surface.

Product positioning: Make three -level precision positioning: internal model tiger mouth positioning, mold embryo guide column positioning, locking positioning while locking

Product cooling: The location of the water running discharge is as consistent as the interval between the product, otherwise the uneven cooling will cause the product to deform

Avoid gaps in the mold: the front and rear molds and other planes should avoid the gap after reserving a certain seal surface. This can not only improve processing accuracy, but also improve processing efficiency

Adding a balance block to the fractal surface of the mold embryo can offset a part of the PL lock mold surface to prevent the internal mold splitting of too fast and the collapse

The top guide column can be used to use a ball guide case or bronze and graphite

The depth depth of the B -board cavity of the mold is thicker as much as possible to avoid deformation of injection molding templates

Each part of the drawing drawing is marked with the tolerance range of processing

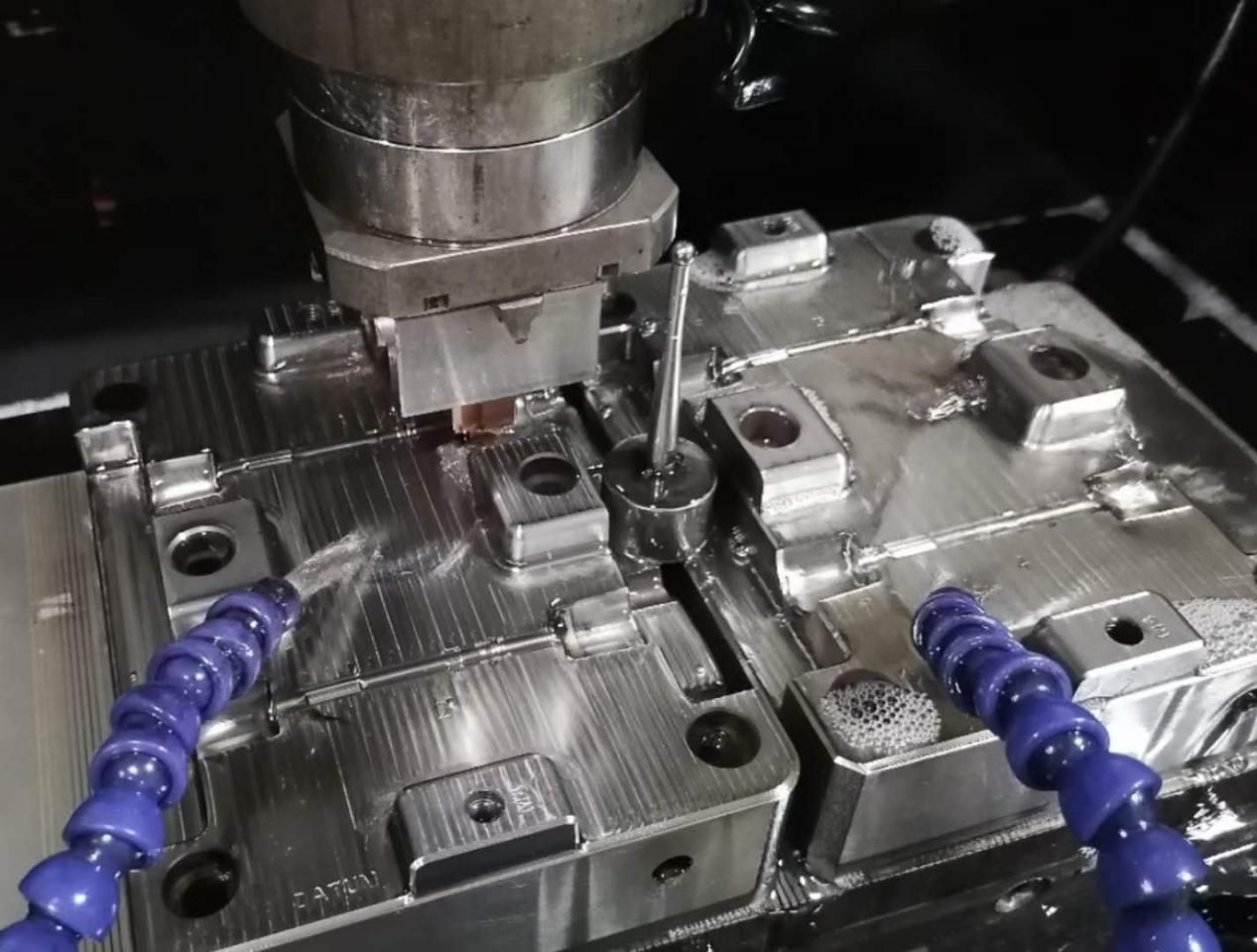

02 Mold processing

Use CNC high -precision machine processing mold core accuracy to achieve 0.02 μ

In order to avoid errors in the four -axis segmentation of each mold processing center, it is best to take shape at one time

Slow wire cutting of the core of the core

Try to use the abrasive bed processing mold inlaid instead of using computer gongs, especially round inlaid

Flying mold cannot be used to use a polished machine, directly on the flying mold machine

Modern embryo accuracy is controlled within 0.02mm, the normal mold is more 0.05mm

Three -dimensional inspection for the electrical grade of the inner mold steel material. Good computer gongs can be directly detected on the machine

Red copper is recommended to use red copper instead of graphite. Although graphite is sparking fast, it is easy to damage the public model, especially the thin steel position

Summary: The precision of the mold requires a full set of reasonable design and processing processes to make it. The problem of each link has an impact on the accuracy of accuracy

For more technical questions, you can consult Chapman Maker team and provide professional technical support.

Email: info@chapmanmaker.com

Post time: Dec-14-2022